Insights Archive

Design Challenge pt 6

This year marked our second year hosting two junior interns from the Ann Richards School for Young Women Leaders. Throughout their week with us, Iris and Sivi were tasked with designing and 3D printing a toolbox that holds items that they use in their daily lives. Below are Iris’s and Sivi’s experiences as they tackle the design challenge. Iris’s Box The original client for my toolbox was my dad. He watches a lot of football on his phone (because the rest of my family does not like football). So I wanted to make a box that could hold up his

Design Challenge pt 5

In our final installment of the design challenge series, Peter thinks outside the box while exploring the parameters of an Altoids tin and Parth fills his toolbox to the brim to include his Raspberry Pi and accessories. Below are Peter‘s and Parth‘s experiences and thoughts on their design challenge. Peter’s Box Who is your client or intended user? The intended user is someone who loves organizing everyday carrying products and hates to throw away usable materials. What tools does your toolbox hold? My toolbox repurposed an existing empty Altoids tin and holds a lip balm and hand sanitizer.

Design Challenge pt 4

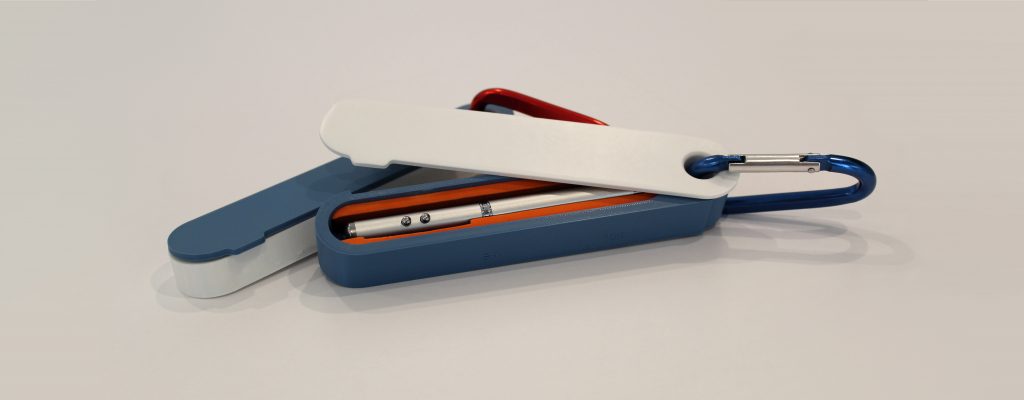

In our fourth installment of the design challenge series, Kevin shows us what 20 years of product development experience looks like. And Raiza is put to the test to learn CAD. Below are Kevin‘s and Raiza‘s experiences and the outcome of their design challenge. Kevin’s Box Who is your client or intended user? I designed it for me. Ultimately, I think someone who values multi-function design would appreciate the box. What tools does your toolbox hold? The purpose of this case is to display a versatile multi-functional tool (such as the one I utilized, which combines a pen, laser

Design Challenge pt 3

In preparation for our two junior interns this summer, we tested their design challenge on ourselves. In our third installment of the series, we explore Robert and Abhi’s designs. Robert’s Box Who is your client or intended user? Before creating my box, I owned this little Harbor Freight X-acto knife set with multiple handle storage. The handles jiggle around and get loose, and I only ever need one handle at a time. I wanted to create a toolbox that would hold one handle, a place to dispose of spent sharps and protect a user from having to dig through a

Design Challenge pt 2

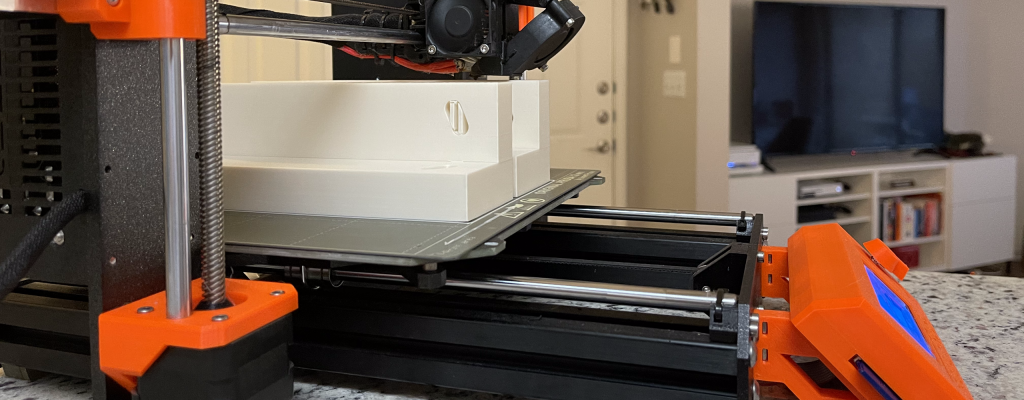

In preparation for our two junior interns this summer, we tested their design challenge on ourselves. It was a rush, getting through all the steps of the design process; brainstorming, sketching, CAD, prototype iteration all in just one week to match Amrutha’s and Valeria’s short time with us. We originally gave the Pump Studios team the challenge of designing a 4” x 6” x 2” container, consisting of at least two parts, that could hold two tools. The requirements were set to help reduce printing size and accommodate a fast turnaround time. As we all got going, we found relaxing

Pump Studios’ Design Challenge

In May, Pump Studios took part in the Ann Richard’s, School For Young Women Leaders, junior internship week. We had the opportunity to host two high school juniors and provide them with real-world work experiences in an educational context. Throughout their week with us, the two girls were tasked with creating a “toolbox” that held at least two tools and had two functioning parts. We defined tools loosely. The girls were asked to bring in “tools” they use in their daily life or hobbies that they would like to create a box around. Below are Amrutha’s and Valeria’s experiences in making

Tools: A Love Story

Let’s take a moment to give a shout-out to an important part of Pump’s team. No matter what needs to be done, they’re always in the shop (sometimes even working outside in the Texas heat), ready to go, and they never complain. A few of them have been around longer than anyone remembers, and will be for years to come. We’re talking about our tools, of course. It’s no secret that engineers love tools. We love using the new ones, the old ones, the big ones, and the small ones. Some are passed down as family heirlooms, and some make

CES 2023

We recently had the opportunity to witness some of the most spectacular displays, experiences, and hottest products at CES 2023. Although we didn’t see anywhere close to everything, we found that our favorite exhibits used automation to solve human problems. Below are our top exciting things that you might have missed. ROBOTICS: RapidPlan by Realtime Robotics With automation and robotics becoming more present in working human environments, prioritizing safety and easy programming is a must. RapidPlan–motion planning software–utilizes click-and-point technology to program robotic arms while minimizing programming time and avoiding collisions. Traditionally, programming happens one robot at a time. With RapidPlan

The Continuous Refinement of Product Requirements

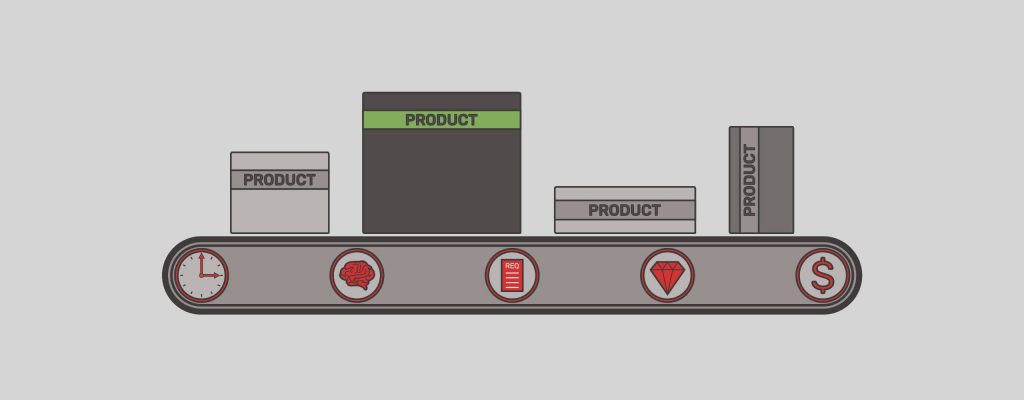

So, you have a great idea. The next thing you want to know is how long will it take and how much will it cost to bring it to life? Most clients who come through our doors at Pump Studios have these questions. The answers require factoring in many variables, but the first step is clearly understanding your requirements. From there, we will determine the complexity and identify what you need to develop your product. The graphic below shows some of the factors used in determining the time and cost for each product. Understand that these factors are unique for

Proudly Celebrating 15 Years!

Like many of our projects, Pump Studios started as an idea—to create a company that was innovative, flexible, and ever-changing for the needs of our clients. A design firm specializing in mechanical engineering with the stability and insight to adapt to our changing environment and the evolving technology of a demanding market. We are proud that over the last 15 years we have stayed true to our vision and enabled our clients to realize their goals through our commitment to a collaborative process that harnesses the latest technology and engineering advancements. The Beginning Pump Studios was founded in 2007 by Brad Collins, Peter

Redesigning Today’s Work Space

Here at Pump Studios, we take products from ideation, to prototype, to production every day. We constantly design, prototype, test, re-design, re-prototype, re-test and repeat to make sure we find the best solution for our clients. Sometimes we are creating a new solution to a problem, other times we are redesigning an existing product to better meet the needs of the current market, in any case, our iterative process is key. One year ago, we had the opportunity to redesign the product closest to us – our work space. Our Work Space, Version 1 – The “Before” We were (and

Building for Today, Designing for Our Future

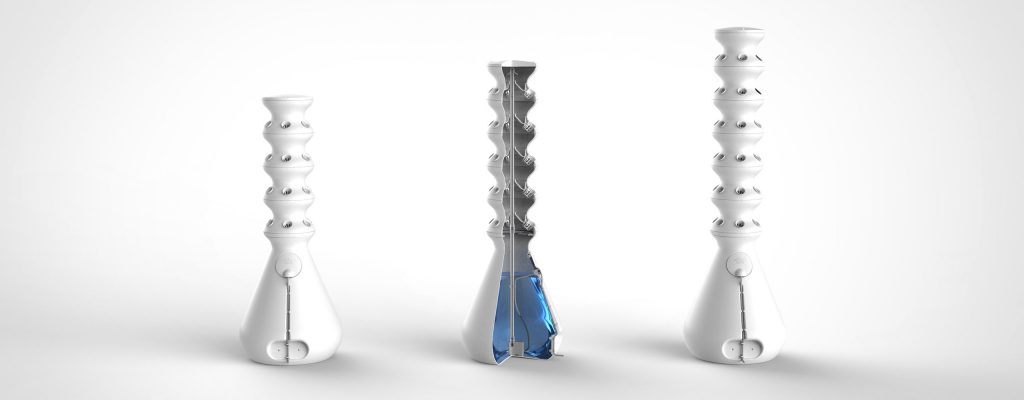

Sustainability. It is a concept and increasingly an innovation imperative, officially shedding some of its last “not a top priority” status. Sustainability is no longer seen as just “a nice to have” in an industry setting and is now being championed as a prominent and shared value among companies, brands, and consumers alike. For Pump Studios and for many of our clients, like Lettuce Grow (who focus on the future of food and at-home farming), sustainability has been a challenging, yet integral, part of our work and services. In a new world of health, safety, and social distancing, we hope to help

The Big Idea

Usually when a startup walks through the door, the project they are pitching is a grand vision – not a refresh of an existing product or a refinement on feature in a larger assembly, but rather a bold vision that will form the basis of a company that will (hopefully) be a successful endeavor for years to come. The biggest idea (literally and figuratively) to come through the door at Pump Studios was the ICON Concrete 3D Printer, the first concrete printer to print a permitted home in the United States. As with most startups, the ICON project had some