Raiza Newberry-Quiroz

So, you have a great idea. The next thing you want to know is how long will it take and how much will it cost to bring it to life? Most clients who come through our doors at Pump Studios have these questions. The answers require factoring in many variables, but the first step is clearly understanding your requirements. From there, we will determine the complexity and identify what you need to develop your product.

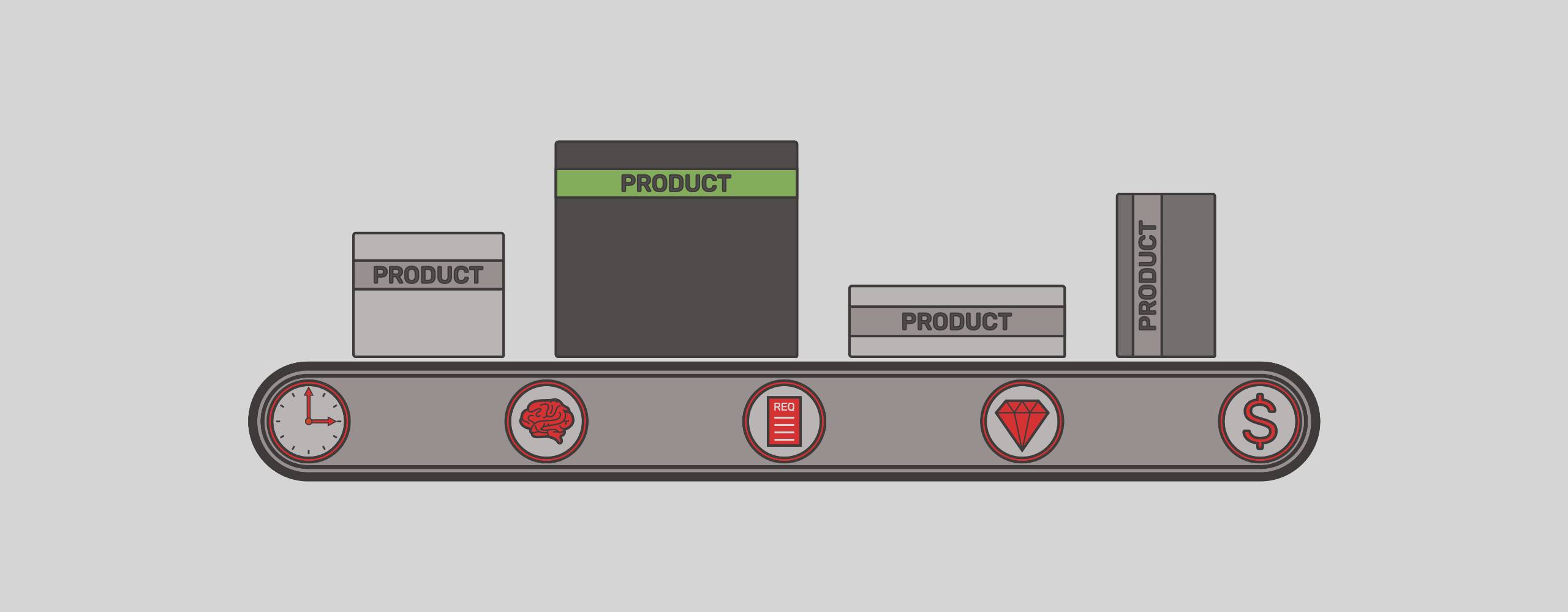

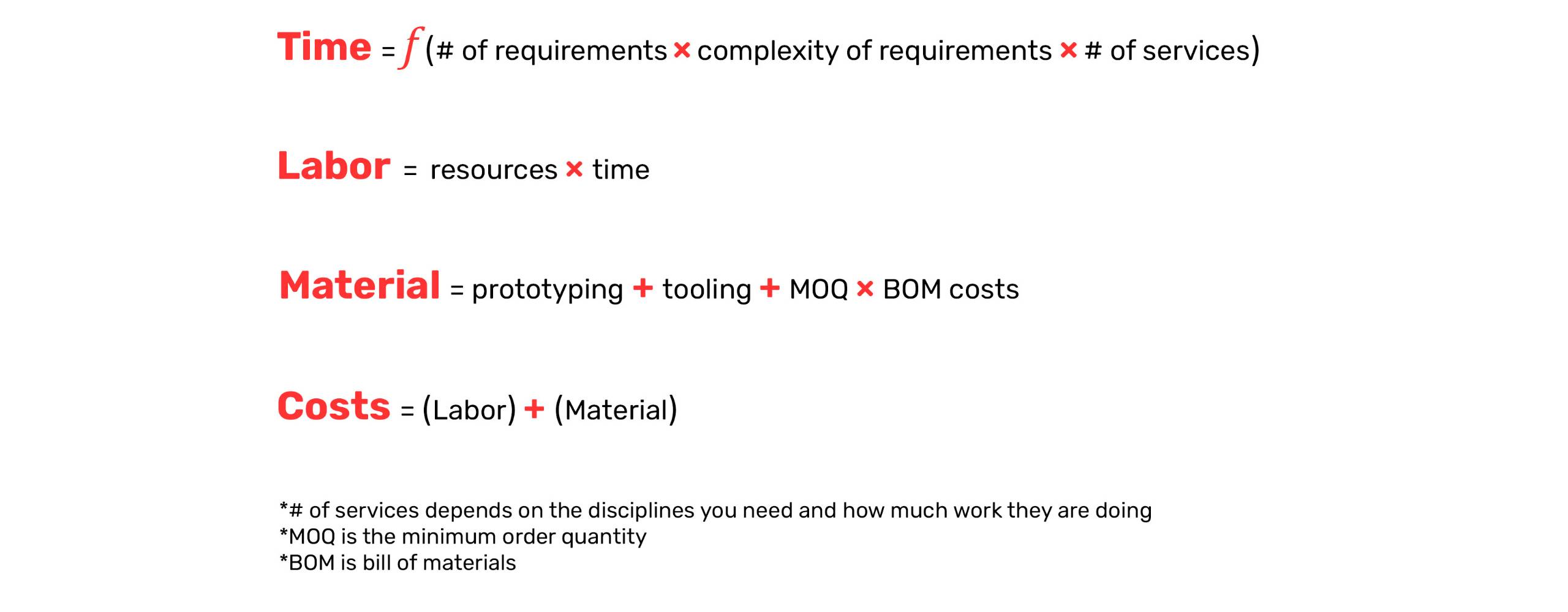

The graphic below shows some of the factors used in determining the time and cost for each product. Understand that these factors are unique for each project and can change throughout the design process.

Project Goals

Before defining your requirements, you should outline the goals for your project. Your project goals are the high-level objectives, the big picture that can affect the course of the design. Step back, take a “10,000-foot view”. Ask yourself “What problem am I trying to solve, how do I want to solve it, who is my end user, and what will it take to satisfy their need?” The requirements of your project become dependent on what you set as your goals.

Examples of project goals: annual sales volumes, environmental impact, BOM cost, manufacturing location, time to market, etc.

The relative importance of each goal depends on the project. For example, a start-up company’s goals may revolve around money and time (getting your product to market fast with limited resources). Using platforms like Kickstarter, Indiegogo, SeedInvest Technology, and Mightycause can provide the initial budget. However, if your fundraising comes up short, your product requirements might need to adapt. Knowing your goals will allow you to assess difficult tradeoffs.

Functional Requirements

Functional requirements are how your product performs, a measurable value that can define success from an engineering perspective. Ultimately, if the product works and the users are happy, that is a success, but it’s hard to measure a happy user. Therefore,we need clear parameters to evaluate against. While different requirements may be associated with a completely new product, industry standards and competitive analysis can be a great starting point until you get into specifics.

Examples of standard requirements: environmental or hermetic sealing requirements (ingress protection rating), drop test specs, operating temperatures, and regulatory standards (UL, CE, etc.).

When contemplating functional requirements for your product, keep in mind what is driving the need for each: Why are you considering water and dust ingress protection? Is it designed to be used outdoors? Does it have embedded electronics? When we worked with the team at iFetch on their interactive fetch toy, they found that the launcher had to function even when a ball was covered in slobber. This specific requirement forced us to adapt and implement gripping features and rework the mechanics to function even when coated in a gelatinous liquid. This hyper-specific requirement tailored the standard around this more important functional requirement.

Examples of specific requirements: able to drive over the product without damaging it, capable of electrical components working inside an internal watering system, able to withstand temperatures of -50 to 120 degrees Fahrenheit, etc.

When one requirement is monumental, others may need to be adjusted accordingly. A very rugged product may prove challenging to make lightweight and small. In cases like this, the functional requirements should be prioritized. When we collaborated with the team at ICON on their second-generation Vulcan 3D concrete printer, functionality, print size, budget, and transportation were competing constraints. We needed to revisit what was most important to the success of the Vulcan II. Unwilling to sacrifice the functionality, and with hard limitations to the budget, we determined that the original idea for how the printers would be transported could change. Reevaluating the conflicting requirements helped us redefine expectations. We settled on having the printer ship on the back of a drop-deck flatbed trailer rather than inside a shipping container. We improved the original design by prioritizing the functional requirements, making the Vulcan II a faster and more efficient concrete printer, while not sacrificing development time and budgetary constraints.

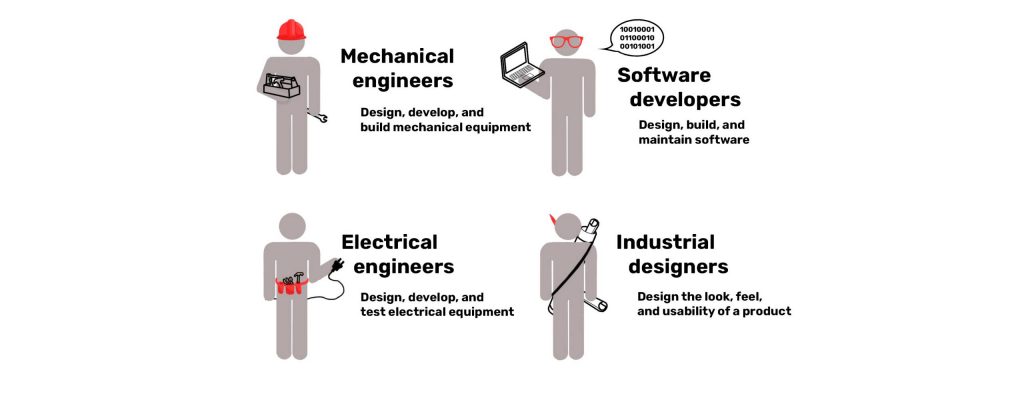

When working with your functional requirements, multiple disciplines are often involved to bring your product to life. Depending on your product and its needs, different team members will be utilized throughout the process. A smaller project might only need mechanical engineers. Keep in mind as you are listing out your requirements that this could potentially impact your financial goals. Listed below are four of the professionals we work with the most.

Industry Requirements

When developing a new product it is important to understand the market category and what regulatory/safety requirements may exist (if any). Medical devices are a basic example of a product with significant regulatory oversight. The industry requirements and your functional requirements are not entirely independent. It’s important to understand how they fit together.

Depending on their use, products fall under different regulations. Regulations may cover health and safety, compatibility, or ensure they don’t interfere with their surroundings. These regulations enforce a standard of safety in equipment when released into a consumer market. Products that have more stringent regulatory requirements might require a regulatory specialist to ensure that your product meets industry requirements. Depending on use, different regulations and approvals must be achieved before you can sell your product.

Examples of regulations: the Food and Drug Administration (FDA), Federal Communications Commission (FCC), the Conformité Européene (CE), and regional standards such as California Proposition 65.

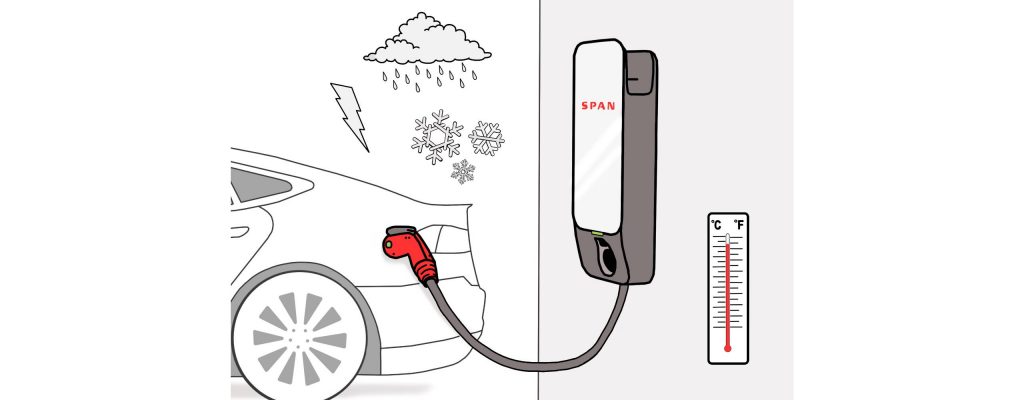

Working with the team at Span on their Span Drive, an at-home electric car charging station, we had to account for the specific regulations and requirements that cover electrical equipment used outside. The Span Drive contains high voltage electrical components. Therefore, it needed an environmental seal to shield it against varying temperatures, rain, sleet, and snow. Designed to specific regulations, the Span Drive had to pass rigorous testing and documentation to deem it safe for the general public to own and use.

Continuous Refinement

As you gain a deeper understanding of the project, the market, and the product, consistently rethink those initial requirements and ask if they still make sense. Going through the development process, some of the original expectations might start to contradict the direction you are taking. Know that your goals and requirements are a continuous balancing act. At the beginning of a project, requirements and goals can seem concrete because we need a place to start, but take a moment to reflect on those requirements and determine if they are still valid. Step back and take that “10,000-foot view”.

In our earlier example of the Vulcan II concrete printer, we had to reanalyze the original idea of transporting a massive printer in a shipping container, shift the goal, and make the printer to be transportable on the back of a flatbed. If you get stuck, ask yourself a few questions to better understand the most important things at this moment. How quickly do we need to get the product to market? How much financing do we have to support the continued development? What is the minimum that this product needs to accomplish in order for it to fully meet customer expectations? The answers could be something you haven’t considered before. A lot can be gained by collaborating with a team of experienced product engineers like Pump Studios. We can offer our clients expertise and experience to help guide them through the fluid process of defining, and then refining, their product requirements.