Libertad Escobar

Here at Pump Studios, we take products from ideation, to prototype, to production every day. We constantly design, prototype, test, re-design, re-prototype, re-test and repeat to make sure we find the best solution for our clients. Sometimes we are creating a new solution to a problem, other times we are redesigning an existing product to better meet the needs of the current market, in any case, our iterative process is key.

One year ago, we had the opportunity to redesign the product closest to us – our work space.

Our Work Space, Version 1 – The “Before”

We were (and still are) a small, collaborative team of mechanical engineers. Work was simple:

- Need to ask a question or just chat? Turn your chair in *any*direction to speak with your coworkers.

- Need to brainstorm some ideas for a project? There are two conference rooms with plenty of paper, markers, and whiteboards.

- Need to build or test prototypes? Walk 10 steps to the workshop abundant with power tools, hardware, and electrical equipment.

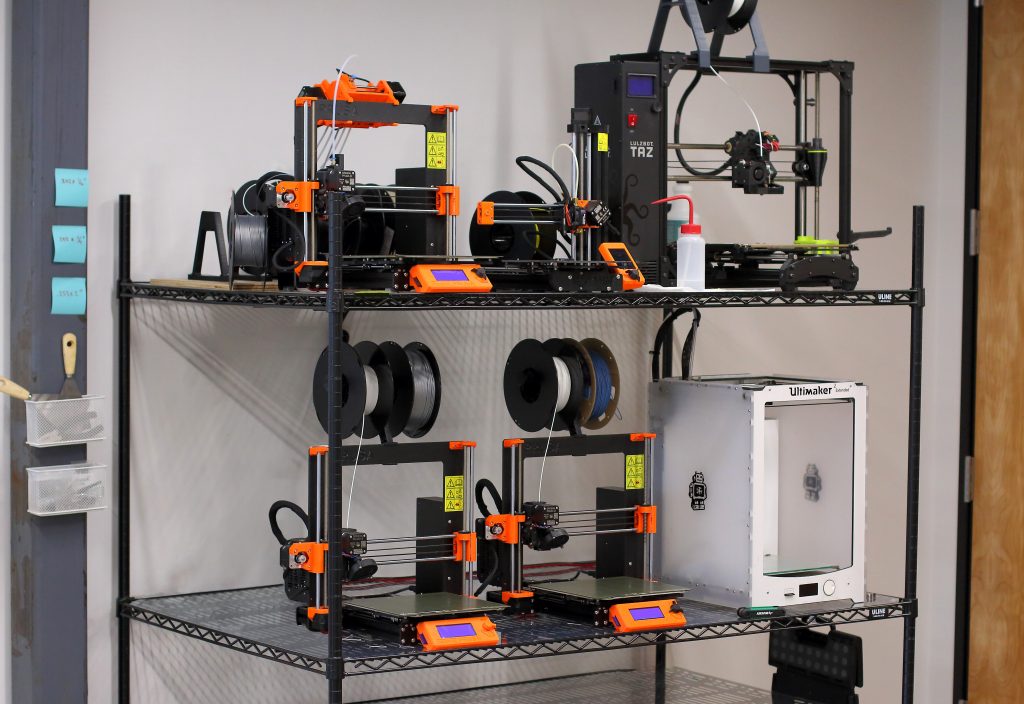

- Need a rapid prototype? There are three 3D printers to choose from.

- Need a midday pick me up? We’re well-stocked in Texas Pecan coffee, granola bars, and Little Debbie snacks.

Working in the office everything was within arm’s reach – the tools, materials, and the people.

Our Work Space, Version 2 – The “Now”

Now things are certainly different. My coworkers are one chat message away on Google Hangouts. Our collaborations take place via Google Meet and Miro. My home “workshop” is now only a drill, assorted screwdrivers, and a hammer. Sure, my 2D printer doesn’t work quite as well as a 3D printer, but it does print in multiple colors! My favorite improvement is that the kitchen is now closer to my desk, and the snacks are a bit more to my individual liking.

Like many others, we’ve learned to adapt and work with the new circumstances. Some things intuitively worked out , or we found workarounds, but as engineers we knew we could do better. So we redesigned.

Prototyping

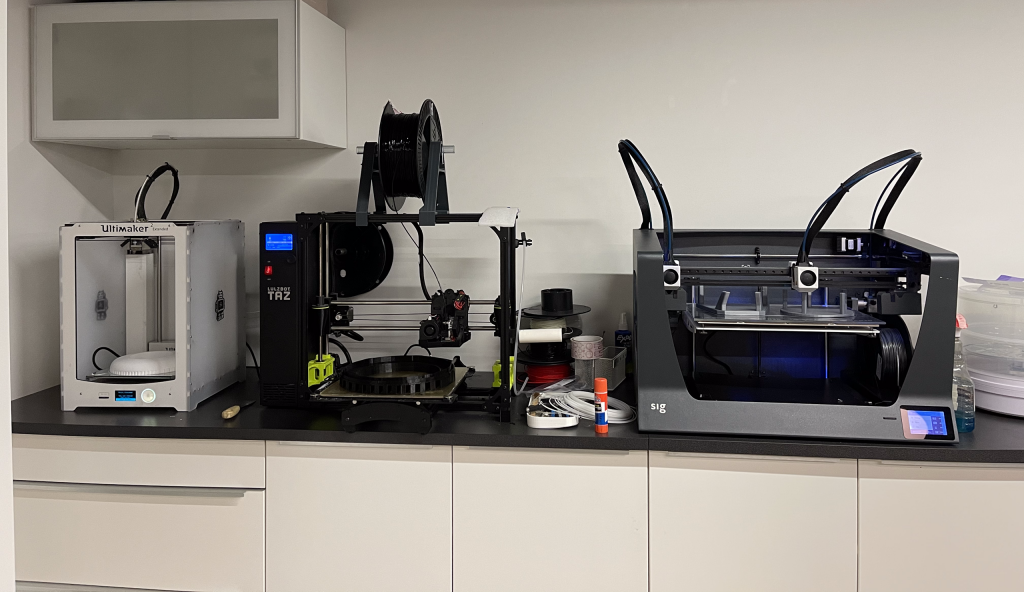

Early on, we realized what we missed most from the office — the 3D printers. It wasn’t realistic (or safe) to go into the office every time we had to start a print, and with only a few printers (one Ultimaker, one Taz, and a broken BCN 3D printer), there were not enough to go around.

Fortuitously, in the beginning of 2020 before the start of the pandemic, one of our coworkers had purchased a Prusa i3 MK3S+ 3D printer that he kindly let everyone use whenever there was a high demand for printing. Honestly, we often asked to use it purely for the exceptional quality prints it produced. After a second coworker purchased their own Prusa, we realized these devices might be the answer to how we prototype from home. We purchased and welcomed three new Prusa I3s and a Prusa Mini printer to our family.

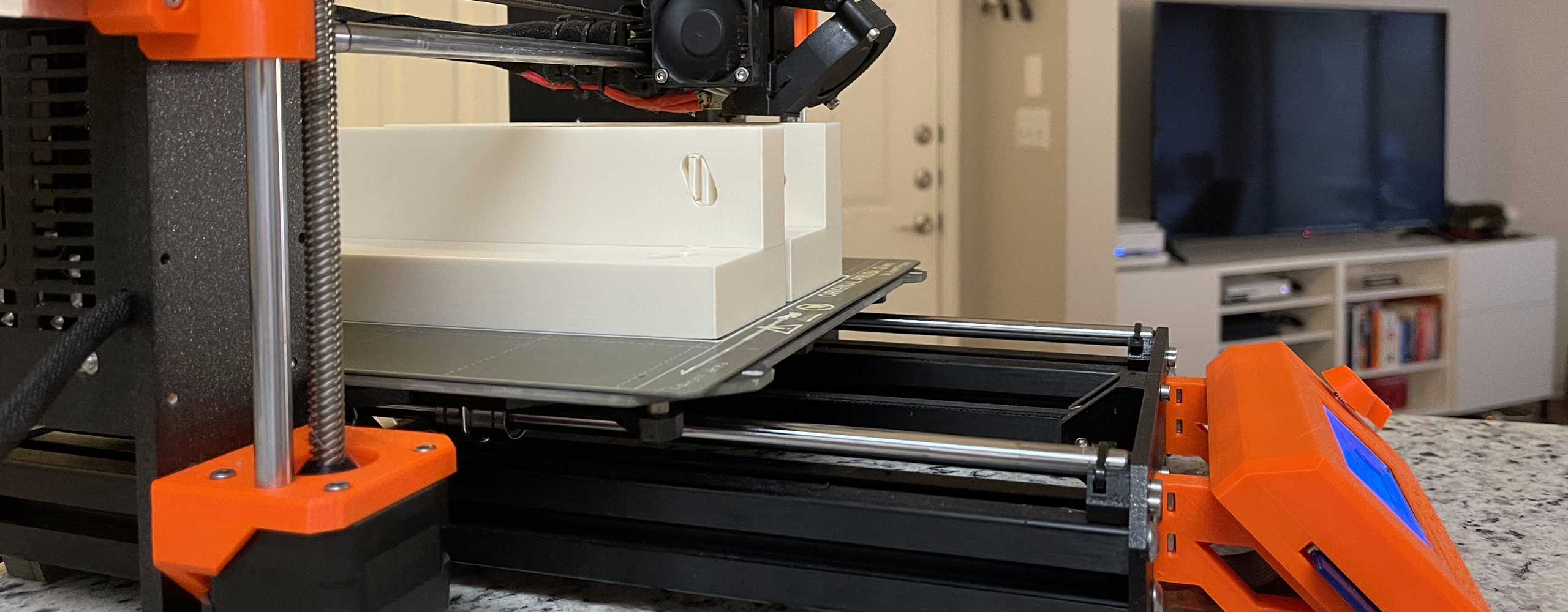

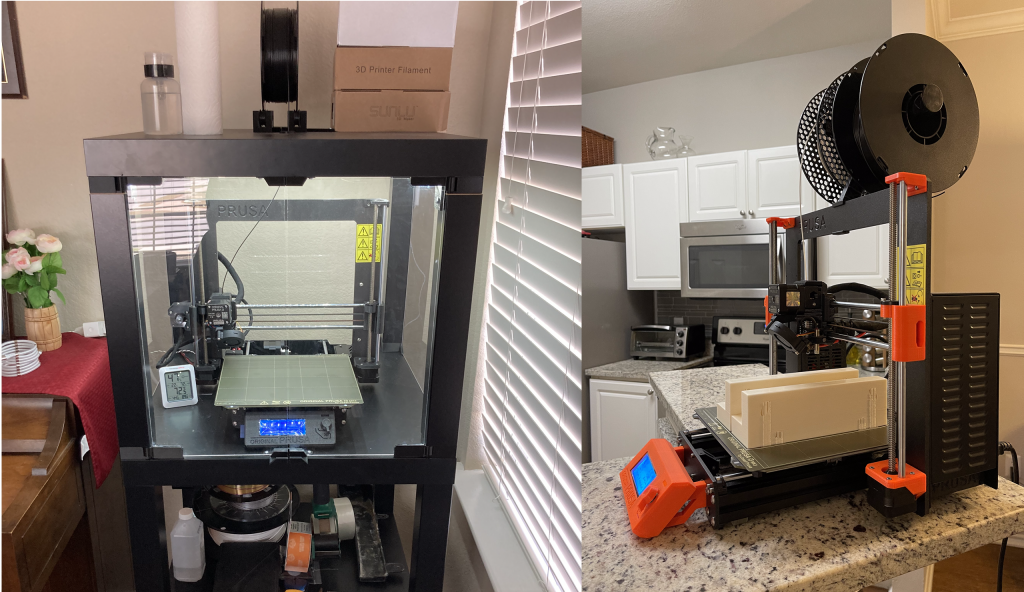

We now have more printers readily available to check out from the office and bring home. The Prusa’s small frame makes it easy to transport, without sacrificing printer bed size and unlike other printers, they require very little calibration (which makes printing between work environments seamless). Another great perk is the removable and flexible printer bed — no more risk of injuring yourself while scraping off a print.

If you don’t mind the neon orange and black color scheme, these printers print like an engineer’s dream. You can see this in action, as they print away on our kitchen counters, spare tables, or in their own custom box (complete with LEDs and acrylic doors).

Collaboration

Brainstorming during a pandemic has surely changed the way we collaborate and share our ideas:

- One method is the “sketching on a piece of paper and holding it up to the webcam and hoping your colleagues can see”.

- A personal favorite is the “taking a picture of your sketch and emailing it to yourself to then screen share to your colleagues”.

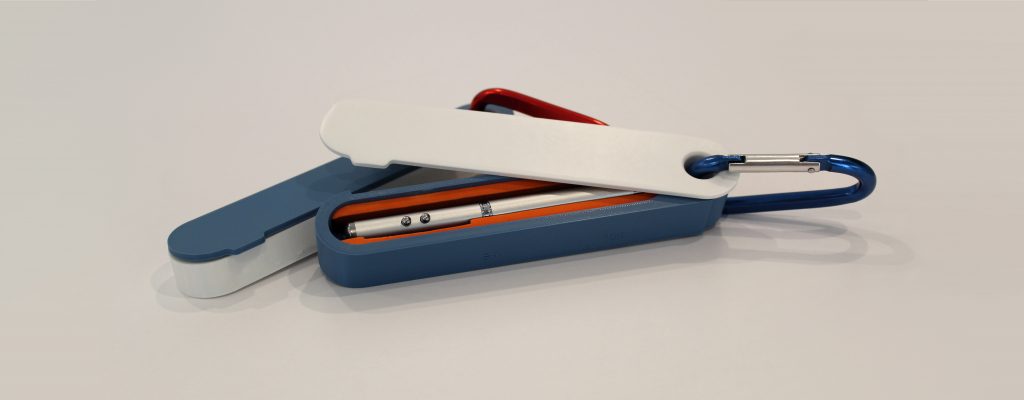

- A third, or more elegant solution, is buying iPad Air tablets and Apple pencils for everyone.

Using our iPads, we can sketch and collaborate on the same document using Miro, while talking to each other through Google Meet. Miro is a web and app based tool that we use as our virtual white board. We can drop images, sketch and take notes in real time.

Some, if not all, of us have made the transition between physical design notebooks to using Good Notes on our tablets to keep digital journals. These journals can even be shared and used as another tool for (almost) in real time brainstorming.

These tablets have changed how easily we communicate and share ideas not just with each other, but our clients as well. Now when we meet with clients, in or out of the office, we can easily take pictures of products and sketch our ideas over top, much easier than drawing freeform. These tablets help us work hard and on occasion play hard as well (we have admittedly all played a couple rounds of Human Fall Flat together).

Our Work Space, Version 3 – The Future: Prototyping and Collaboration

Collaboration with clients whether they are local or across the world doesn’t always mean the sharing of 2-dimensional ideas, but physical prototypes as well. We often find ourselves shipping prototypes or couriering them across town (often at much greater expense than the cost of the prototype). One of our long-standing clients had engineers working from Austin, New York, and Taiwan, which made sharing prototypes even more challenging. Having heard how well the Prusas worked for us, they asked us to help set up their own fleet of Prusa printers to make working from home more efficient. By supplying their engineers and designers around the world with printers, collaboration has become easier. Instead of having to ship prototypes we can just email STL (printable format) files instead.

One large resource that we couldn’t quite bring home was our workshop. The large power tools, electrical equipment, and workbenches certainly do not fit into our cars (or in some of our apartments). For more than half of the pandemic year, we managed what we could at home. Now that we are able to use the office (in compliance with the CDC guidelines), we developed a new resource to manage the blended “work from home and from the office” style. Our “In The Office” calendar (a spinoff of our “Out Of Office” calendar) helps us track and manage when and who will be in the office.

As we start to move forward, tools like these will certainly stay with us as our workspace evolves to meet the demands of the world we live in. And who knows? Maybe one day Pump Studios will engineer a way to transport our workshop anywhere…

The Tools We Use:

- Prusa 3D Printers: https://www.prusa3d.com/

- Prusa Enclosure: https://blog.prusaprinters.org/cheap-simple-3d-printer-enclosure_7785/

- Apple iPad Air: https://www.apple.com/ipad-air/

- Apple Pencil: https://www.apple.com/apple-pencil/

- Miro: https://miro.com/

- GoodNotes: https://www.goodnotes.com/