Peter Kaltenbach

Sustainability. It is a concept and increasingly an innovation imperative, officially shedding some of its last “not a top priority” status. Sustainability is no longer seen as just “a nice to have” in an industry setting and is now being championed as a prominent and shared value among companies, brands, and consumers alike.

For Pump Studios and for many of our clients, like Lettuce Grow (who focus on the future of food and at-home farming), sustainability has been a challenging, yet integral, part of our work and services. In a new world of health, safety, and social distancing, we hope to help make the integration of sustainable and mindful design more accessible for even more industries, people, and communities. Building for now doesn’t mean we can’t design for the future. Here are some thoughts to keep in mind as many assess and plan for 2021.

Minding the Mission

First things first, make sustainability an active ingredient and measurement of success across all levels. We’ve all probably heard the saying “invest for your future”, and that is exactly what it looks like, taking the time, funds, resources, and more to ensure sustainability is a part of your process and culture. Doing so will ensure the viability of your mission, product, and company for the long-term.

For our client at Lettuce Grow, understanding the origin of one’s food is key to the Lettuce Grow mission, and it is tightly tied to sustainable and responsible practices in the full lifecycle of the product. As a result, Pump Studios carefully selected materials that were safe, had a high post-consumer/recycled content, and could be recycled easily at the end of their (long) life span.

Challenges may rise but you don’t have to compromise

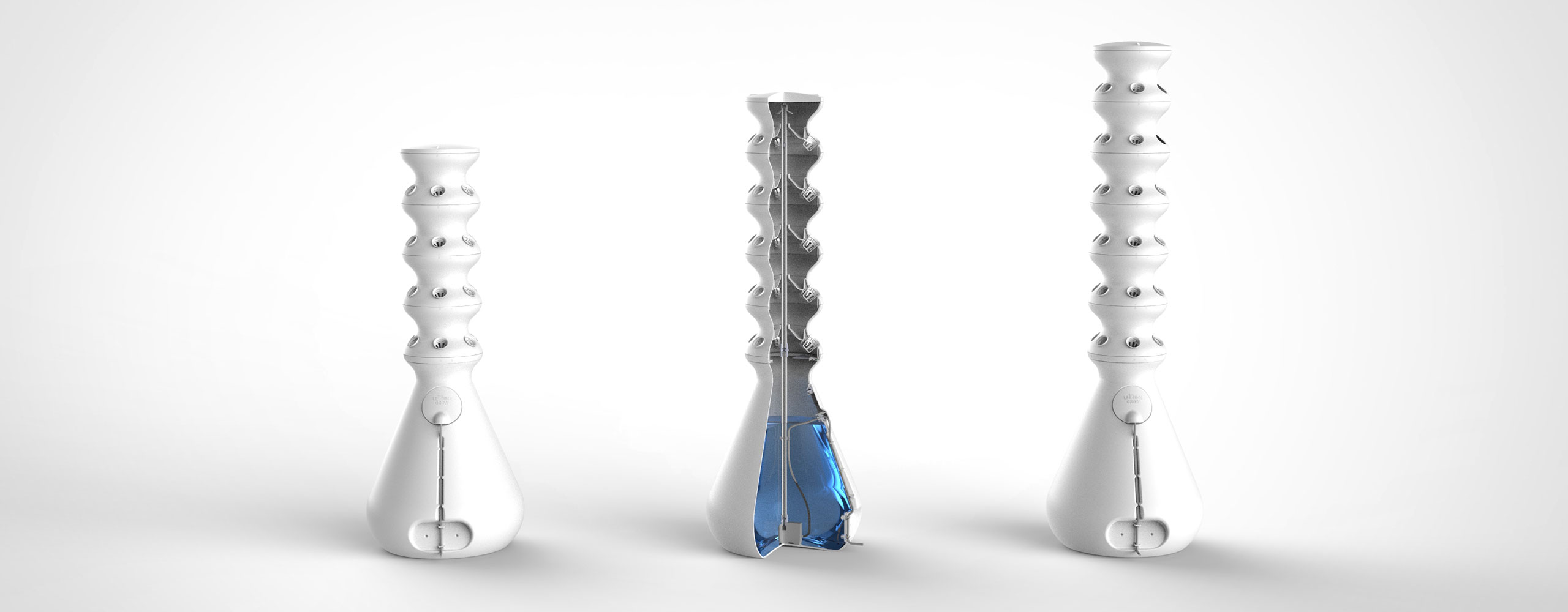

The Lettuce Grow Farmstand project came to us several years ago with the need to develop a unique aeroponic growing tower, which would allow users to grow their own food in a small footprint. They needed a design that is visually striking, easy to use, safe (free from harmful substances and chemicals), and cost effective.

However, many in the industry are wary of using recycled content in production due to safety concerns or concerns with production challenges. Naturally, consumers are also sensitive to the safety of the materials they bring into their homes, especially in terms of their food. In a post-COVID era, authenticity and trust go hand in hand (and with many are a must) with receiving a quality product or service. By being transparent about your values, process, materials, testing, marketing, the steps you are taking to care for and/or serve your audiences, and everything in between, you work to not compromise yourself while organically building that bridge of trust.

Over the years, many clients have started a project with a goal of using recycled/sustainable materials and manufacturing in the US. Unfortunately, once they understand the financial implications and challenges, they often default to tried-and-true materials and overseas manufacturing. This is not uncommon across industries, and the reasons vary; however, those who have been able to not only overcome but shift this paradigm, holding their ground and making sustainability and carefully constructed supply chains a part of their DNA, have been playing the long game. Now catalysts, they have a creditable stake in this evolving ethos and are leading the charge when it comes to trusted sustainable design and valued products/services.

Be ready to meet your consumer today & tomorrow

Our society revels in a culture of immediate gratification and a “I need that now” mentality, so it may be difficult to get excited about planning or building for our future. But as we all know, time flies, and with time comes change, and sometimes very swift unprecedented changes. The need for sustainability, and the ability to adapt, have never been more evident and those who have been living in this space are more than ready to mobilize.

Case in point, during the global disruptions in supply chains, both for food and product (due to COVID-19), consumers have become increasingly more aware of the origin of their food and are extremely selective when it comes to choosing a product, opting for durable goods with minimal environmental impact rather than fleeting experiences. The Lettuce Grow Farmstand is a product that provides lasting value, ongoing production of food, and is made in part from recycled materials. Their products are made from Ocean-Bound plastic (recovered from coastal communities), meets CA Proposition 65 for reduction of harmful materials, and uses 95% less water than traditional gardening, staying true to their mission for sustainability and helping customers do, and feel, good. In addition, Lettuce Grow’s carefully constructed supply chain, (based in the U.S.) reduces the impact of added logistics and shipping, and is much less susceptible to global business changes.

Don’t be afraid to learn, lead & inspire

Over the years at Pump Studios, and in each project we take on, we overcome new challenges and wear new/many hats. Throughout we always use what we learn to enhance our expertise and inspire our team, our clients, and our community.

With Lettuce Grow, we created a beautiful solution for home farming and have become avid users and advocates for growing our food at home ourselves. Inspired, we encourage all to:

- Turn sustainability into a primary mindset

- Work through the challenges, even when the challenges seem insurmountable

- Champion partners who are passionate about what they do and where you can share their passion

We are proud to help our partners build for now while planning for the future through sustainable design. And in the spirit of our client example: this new year, LET US GROW TOGETHER.