Design Challenge pt 6

This year marked our second year hosting two junior interns from the Ann Richards School for Young Women Leaders. Throughout their week with us, Iris and Sivi were tasked with designing and 3D printing a toolbox that holds items that they use in their daily lives. Below are Iris’s and Sivi’s experiences as they tackle the design challenge. Iris’s Box The original client for my toolbox was my dad. He watches a lot of football on his phone (because the rest of my family does not like football). So I wanted to make a box that could hold up his

Design Challenge pt 5

In our final installment of the design challenge series, Peter thinks outside the box while exploring the parameters of an Altoids tin and Parth fills his toolbox to the brim to include his Raspberry Pi and accessories. Below are Peter‘s and Parth‘s experiences and thoughts on their design challenge. Peter’s Box Who is your client or intended user? The intended user is someone who loves organizing everyday carrying products and hates to throw away usable materials. What tools does your toolbox hold? My toolbox repurposed an existing empty Altoids tin and holds a lip balm and hand sanitizer.

Design Challenge pt 4

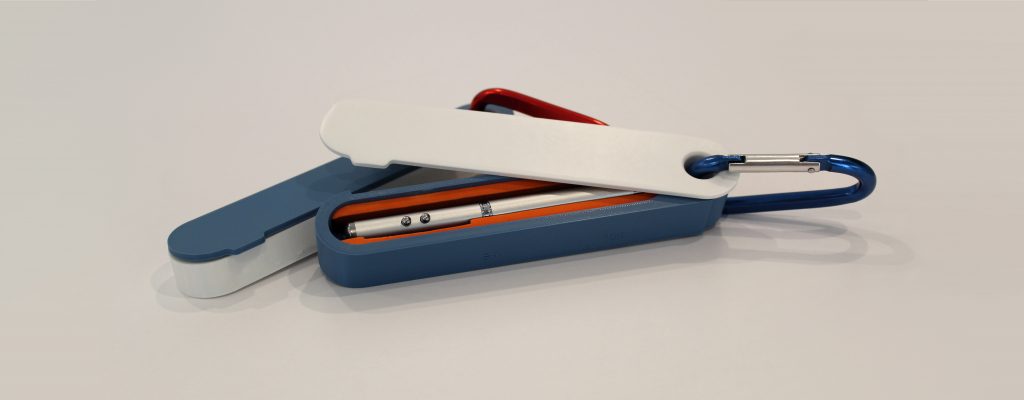

In our fourth installment of the design challenge series, Kevin shows us what 20 years of product development experience looks like. And Raiza is put to the test to learn CAD. Below are Kevin‘s and Raiza‘s experiences and the outcome of their design challenge. Kevin’s Box Who is your client or intended user? I designed it for me. Ultimately, I think someone who values multi-function design would appreciate the box. What tools does your toolbox hold? The purpose of this case is to display a versatile multi-functional tool (such as the one I utilized, which combines a pen, laser

Design Challenge pt 3

In preparation for our two junior interns this summer, we tested their design challenge on ourselves. In our third installment of the series, we explore Robert and Abhi’s designs. Robert’s Box Who is your client or intended user? Before creating my box, I owned this little Harbor Freight X-acto knife set with multiple handle storage. The handles jiggle around and get loose, and I only ever need one handle at a time. I wanted to create a toolbox that would hold one handle, a place to dispose of spent sharps and protect a user from having to dig through a

Design Challenge pt 2

In preparation for our two junior interns this summer, we tested their design challenge on ourselves. It was a rush, getting through all the steps of the design process; brainstorming, sketching, CAD, prototype iteration all in just one week to match Amrutha’s and Valeria’s short time with us. We originally gave the Pump Studios team the challenge of designing a 4” x 6” x 2” container, consisting of at least two parts, that could hold two tools. The requirements were set to help reduce printing size and accommodate a fast turnaround time. As we all got going, we found relaxing

Pump Studios’ Design Challenge

In May, Pump Studios took part in the Ann Richard’s, School For Young Women Leaders, junior internship week. We had the opportunity to host two high school juniors and provide them with real-world work experiences in an educational context. Throughout their week with us, the two girls were tasked with creating a “toolbox” that held at least two tools and had two functioning parts. We defined tools loosely. The girls were asked to bring in “tools” they use in their daily life or hobbies that they would like to create a box around. Below are Amrutha’s and Valeria’s experiences in making