Air Mover Test Plenum

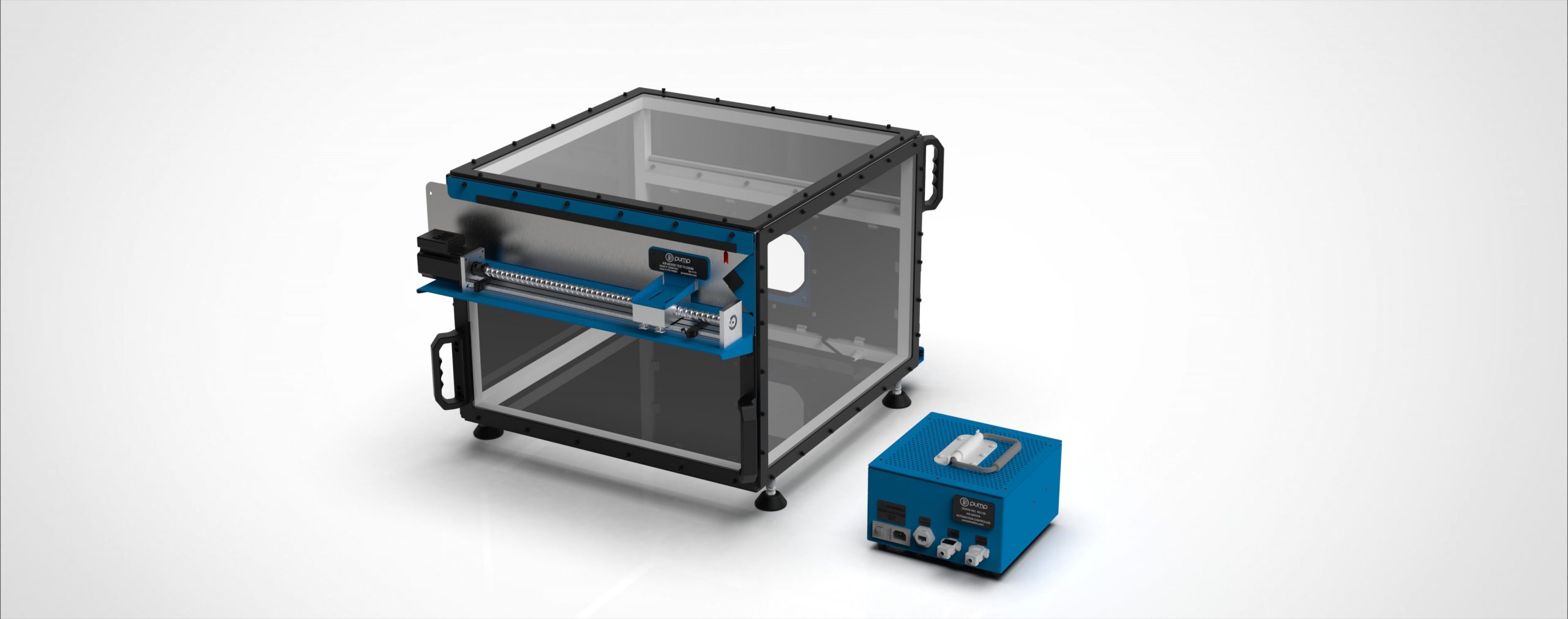

To support manufacturers in evaluating the acoustic performance of fans and blowers, we developed a precision air mover test plenum based on ISO 10302-1, which defines methods for measuring airborne noise from small air-moving devices (AMDs). The standard ensures consistent, comparable results for manufacturers and testing labs, supporting engineering validation and performance verification.

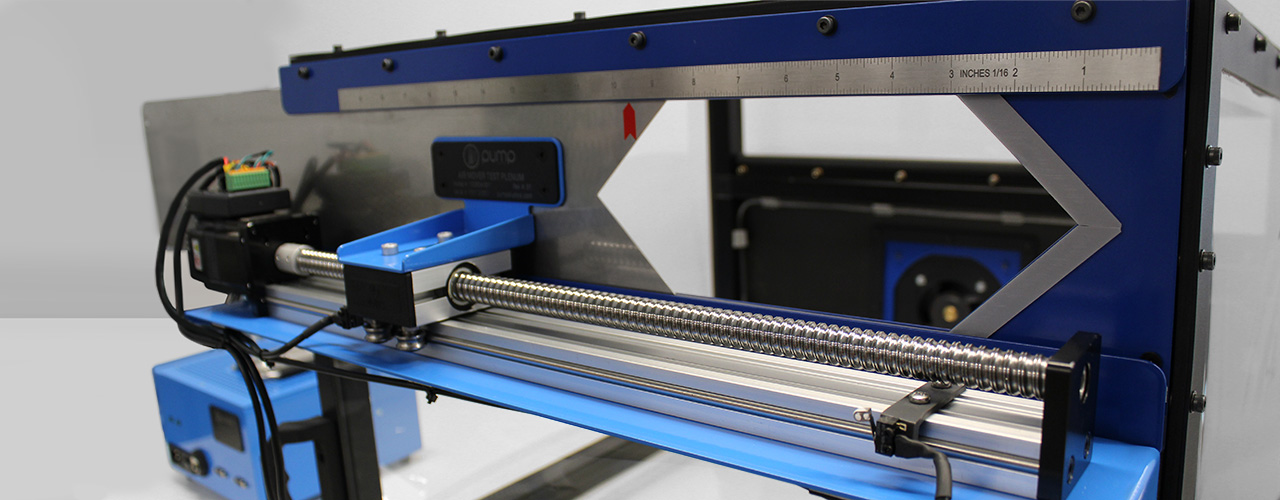

We designed and built two versions of the Pump SMARTFlow test plenum. The first version is a base model that conforms to ISO 10302-1, capable of measuring sound power levels across a range of airflow and pressure conditions. The design minimizes acoustic reflections and is built for seamless integration with existing lab setups delivering accurate and repeatable results. In the base configuration, the user manually adjusts the sliding damper to reach a desired operating point, and measures pressure with an external device.

The second version was in response to a customer request. Pump introduced automated aperture control with pressure set point functionality. We implemented a closed-loop system that can automatically set and maintain a target pressure. The system was designed for low acoustic impact and easy lab integration. The modular design provides a flexible, standards-based testing platform that simplifies test procedures and delivers high-confidence acoustic measurements.

Contributions

- Detailed Design

- Design Implementation

- Prototyping and Validation

- Testing and Refinement

- Sourcing and Manufacturing Support